Tool Box

Sketch

The first step of making the tool box was making a sketch. A good sketch should have dimensions, a scale ratio, and at least 4 different views of the piece.

CAD

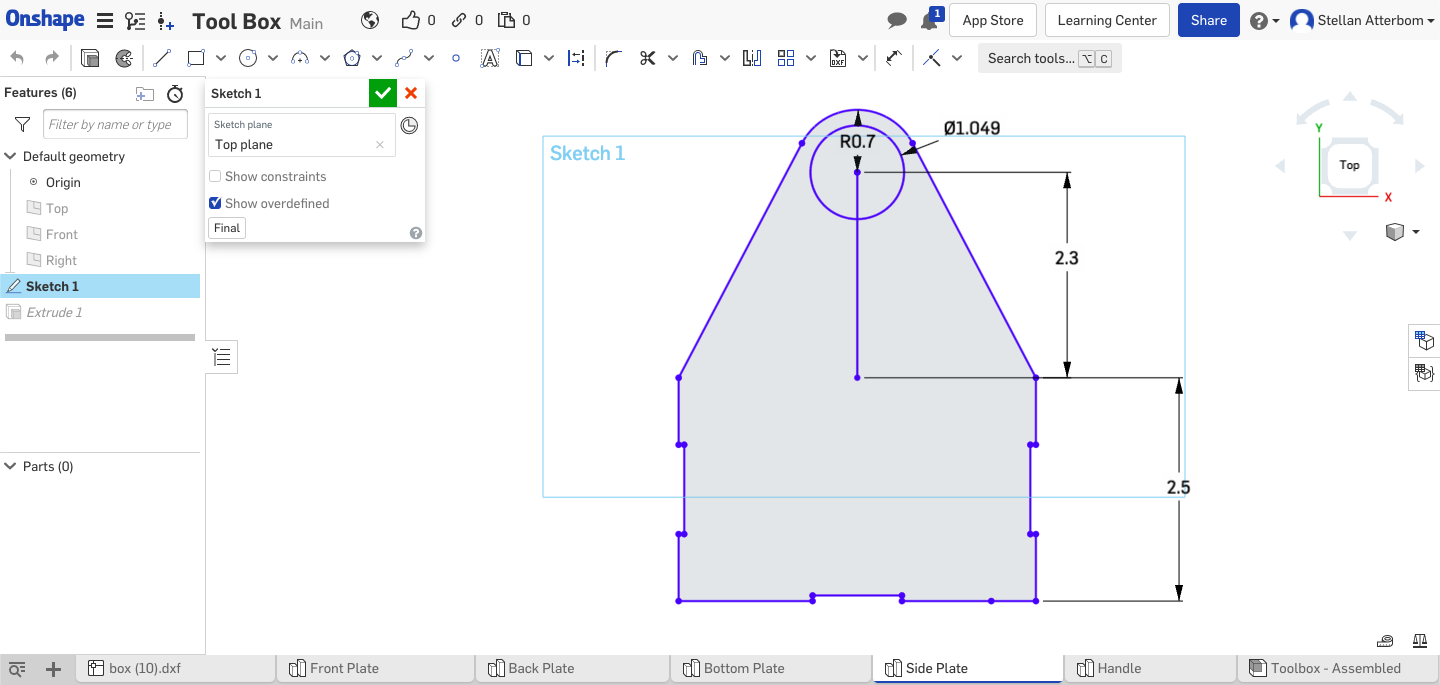

After the sketch, I put my dimensions into Maker Case (software) to help me create the general shape of my tool box. From there, I put the Maker Case file into Onshape to complete my design. The two pictures to the right are my completed side plate and the file I brought in from Maker Case. The picture below is my completely assembled box.

Cut

I then used the CAD to cut my parts on the water jet. I used 16th inch steel to make the toolbox. After I cut my parts, I washed and dried them.

Weld

Now, I needed to weld my parts. I used a belt sander to remove the tabs from the water jet and then used wire brushes to brush the joints of my box to make sure they were clean for welding. Next, I welded my box and then cleaned it again.

On the right is the welding table we used.

The Final Product